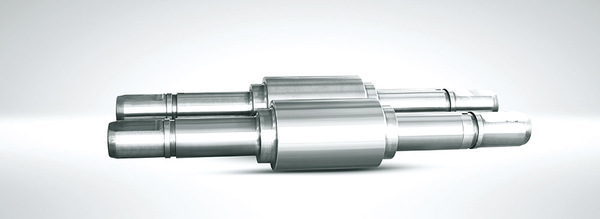

Rolling mill roll is a tool for plastic deformation of rolled metal, which is an important consumption part to determine the efficiency of rolling mill and the quality of rolled products. Roll is an important part of rolling mill. The rolling pressure of a pair or group of rollers is used to roll steel. It mainly bears the influence of static and dynamic load, wear and temperature change during rolling.

There are many kinds of rolls, including cast steel rolls, cast iron rolls and forging rolls. There are also a few cemented carbide rolls (tungsten steel rolls) on profile mills.

According to the molding method:

Casting roll and forging roll.

Casting roll refers to the type of roll made by casting molten steel or molten iron directly.

Casting roll can be divided into cast steel roll and cast iron roll according to material, and can be divided into integral casting roll and compound casting roll according to the manufacturing method.

The forging roll is classified as follows according to the material:

(1) Forging alloy steel roll;

(2) Forging semi-steel roll;

(3) Forging semi high-speed steel roll;

(4) Forging white cast iron roll.

According to the process method:

Integral roll, metallurgical composite roll and combined roll.

1. Compared with the composite roll, the outer layer and core of the roll body and the roll neck of the integral roll are cast or forged by single material. The different microstructure and properties of the outer layer and neck of the roll body are controlled and adjusted by casting or forging process and heat treatment process. Both forging roll and static casting roll belong to integral roll. Integral roll can be divided into integral casting roll and integral forging roll;

2. There are mainly three kinds of metallurgical composite casting roll, such as semi washing composite casting, overflow (full washing) composite casting and centrifugal composite casting. In addition, there are some special composite methods such as CPC-Continuous Pouring Process for Cladding, spray deposition, HIP-Hot Isostatically Pressed. The composite roll is mainly inlaid composite roll.

According to manufacturing materials:

Cast steel rolls, cast iron rolls and forging rolls.

The commonly used heat treatment types of roller are stress relief annealing, isothermal spheroidizing annealing, diffusion annealing, normalizing, tempering, quenching and cryogenic treatment.

According to the shape of roller body:

There are different classification methods for rollers. The former is mainly used for plate, strip, profile and wire production, while the latter is mainly used for pipe production.

According to contact with rolled piece or not:

It is divided into work roll and backup roll. The roll that directly contacts the rolled piece is called the work roll; the roll which is placed on the back or side of the work roll and does not directly contact the workpiece is called the backup roll in order to increase the stiffness and strength of the work roll.

According to the rack used:

It is divided into primary roll, roughing roll, intermediate roll and finishing roll according to the use stand. According to the variety of rolled products, it can be divided into strip roll, rail beam roll, wire roller and pipe roll, etc. It can also be divided into hot roll and cold roll according to the state of rolled piece during rolling.

According to hardness value:

(1) The shore hardness of soft roll is about 30 ~ 40, which is used in embryo opening machine and roughing mill of large section steel rolling mill.

(2) The shore hardness of semi-hard roll is about 40 ~ 60. It is used in roughing mill of large, medium and small section mills and plate mills.

(3) The shore hardness of hard surface roll is about 60 ~ 85, which is used for roughing mill of thin plate, medium plate, medium section steel and small section steel mill and the support roll of four high rolling mill.

(4) The shore hardness of super hard roll is about 85 ~ 100, which is used in cold rolling mill.

According to hardness value:

(1) The shore hardness of soft roll is about 30 ~ 40, which is used in embryo opening machine and roughing mill of large section steel rolling mill.

(2) The shore hardness of semi-hard roll is about 40 ~ 60. It is used in roughing mill of large, medium and small section mills and plate mills.

(3) The shore hardness of hard surface roll is about 60 ~ 85, which is used for roughing mill of thin plate, medium plate, medium section steel and small section steel mill and the support roll of four high rolling mill.

(4) The shore hardness of super hard roll is about 85 ~ 100, which is used in cold rolling mill.

According to the type of rolling mill:

(1) Flat roll. That is, the roll body of plate and strip mill is cylindrical. Generally, the roll of hot rolling plate rolling mill is made into micro concave shape, which can obtain better shape when heated; the roll of cold rolling plate rolling mill is made of micro convex shape, and the roll will bend during rolling to obtain good shape.

(2) Grooved roll. It is used for rolling large, medium and small section steel, wire rod and blooming. A groove is carved on the roll surface to form the rolled piece.

(3) Special roll. It is used in steel tube rolling mill, wheel rolling mill, steel ball rolling mill and piercing mill. The rolls of this kind of rolling mill have various shapes. For example, the rolls rolled by the principle of cross rolling in steel pipe rolling are conical, waist drum or disc.

If you are interested in our rolling mill rolls, please send your inquiry to marketing2@hanrm.com.

Whatsapp / Wechat: +8618392033938

More Articles You May Be Interested in:

10. Roller FAQs

Thanks for shared that blog with us. If anyone here searching SS 304 pipe suppliers in India then visit Raaj Sagar Steels.

ReplyDeleteYour contents are completely awesome and share worthy. I really appreciate your efforts that you pfforts that you put on this. Keep sharing. For more 304 Stainless Steel Tube Suppliers related information visit triloksteel.

ReplyDelete