The shears used for transverse shearing of moving rolled pieces are called flying shears. With the development of continuous steel plate mills, section steel mills and billet mills and the improvement of flying shear productivity, flying shear is more and more widely used.

There are many types of flying shears, which are widely used: disc flying shears, double drum flying shears, crank rotary and pendulum flying shears, etc.

1. Disc-type Flying Shear

This kind of flying shear is generally used in the small rolling locomotive rooms. It is installed in front of the cooling bed to roughly cut the rolled pieces so that the rolled pieces entering the cooling bed will not be too long; before installation in the finishing mill, the rolled piece shall be cut to ensure the smooth-rolling process of the finishing mill. The flying shear is composed of two or more pairs of disc-shaped blades, and the axis of the disc is equal to the moving speed of the steel.

When the flying shear is in the original position, the steel advances along the inlet duct to the left of the flying shear. When the steel acts on the flag switch or optical waveguide, the inlet conduit and the steel deflect to the right, and the steel enters the middle of the two discs for shearing. After the lower blade descends, the guide tube returns the steel to the original left position, and then the lower blade rises again. The disadvantage of this kind of flying shear is that the cut is inclined, but it has little effect on the rough cutting of rolled pieces before cutting or cooling beds. Due to its reliable operation, simple structure, and shearing speed of more than 10m/s, the shear has been widely used in small rolling locomotives.

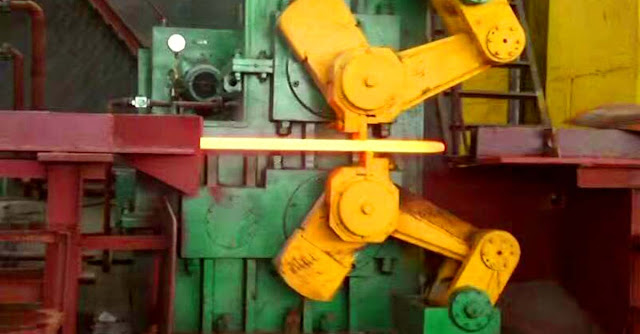

2. Double Drum Flying Shears

Double drum flying shears are widely used to shear steel sections and plates in motion. Their working principles are as follows:

On the two rotating rollers, two blades are fixed radially. When the rolled piece moving along the roller table passes through the middle of the two rollers, it is sheared by the two blades that meet. The circumferential speed of the blade shall be slightly greater than the moving speed of the rolled piece, otherwise, the rolled piece will bend at the inlet during shearing.

The disadvantage of this kind of flying shear is that the section is not smooth when cutting thick rolled pieces (it has too much influence on cutting thin rolled pieces); When cutting wide steel plate, the shear force is large. Therefore, this kind of flying shear is used to shear small sections and thin plates of high-speed rolled pieces.

3. Crank Rotary Flying Shear

Its shearing mechanism is composed of a four-bar linkage mechanism, and the shearing edge moves in an approximate plane in the shearing area and is perpendicular to the surface of the rolling piece. Therefore, the cut section of the rolled piece is relatively straight. The shearing mechanism of the flying shear is composed of a tool holder, an eccentric sleeve, and a swing rod. The tool holder is in the shape of a lever, one end of which is fixed on the eccentric sleeve, and the other end is connected with a swing rod. The swing fulcrum of the swing rod is hinged to the column.

When the eccentric sleeve (crank) rotates, the tool holder moves in translation, and the blade fixed on the tool holder can be perpendicular or approximately perpendicular to the rolling piece. When shearing steel plates, an oblique blade can be used to reduce the shearing force. The disadvantage of this flying shear is that the structure is complex, the dynamic load characteristics of the shearing mechanism are poor, and the movement speed of the blade cannot be too fast. Generally used for shearing thick steel plates or billets.

4. Pendulum Flying Shear

The pendulum flying shear is sometimes used in the cross-cutting unit of the continuous steel plate rolling locomotive. The blade of the flying shear also makes translational movement, and the quality of cutting plates is good. The upper tool rest is fixed on the swing frame. The swing frame is supported by the eccentricity of the main shaft. There are two pairs of eccentricities on the main shaft, of which the other pair is connected with the lower tool rest through the connecting rod, and the lower tool rest can slide into the chute of the swing frame. Due to the difference of 180 ° between the two eccentric positions on the main shaft, when the main shaft rotates, the upper tool rest descends with the frame, while the lower tool rest rises to complete the shearing action. However, it can only shear stationary rolled pieces.

In order to shear the moving rolled piece, it is necessary to make the swing frame swing back and forth. The lower part of the swing frame is hinged with an eccentric rod, and the eccentric wheel is installed on the rear axle. The rear axle is connected to the main shaft through pinion, rack, and synchronizing disc. When the spindle rotates, the frame can swing back and forth with the spindle as the center by synchronizing the disc, rack, pinion, and the eccentric connecting rod on the rear axle. At this time, the tool rest moves in translation to realize the cutting work of the pendulum flying shear.

The role of shears in the rolling mill is not the key position, but it plays a vital role in the accuracy and shape of finished products. Different types of rolling mills should select the corresponding flying shears, so that the whole production line can achieve the target size and accuracy.

If you are interested in the shearing machine of rolling mill, please contact me freely.

Email: marketing2@hanrm.com; inquiry88@metallurgy.com; kerrirollingmill@gmail.com.

Whatsapp & Wechat:+86 18392033938

Website: www.hanrm.com; www.hanmetallurgy.com; www.steelrollingmillmachine.com

Kindly click on the article you are interested in:

Hot Rolled Steel and Cold Rolled Steel

Hot Rolled Steel Plate VS Cold Rolled Steel Plate

What is Metallurgical Equipment?

Multi-roll Mill VS Common Mill?

Hot Rolling Process VS Cold Rolling Process

Finishing Rolling Mill Process Explanation

Three Basic Laws of Steel Rolling

Reasons and Solutions for the Piling of Wire Rod Rolling

The Main Rolling Processes of the Wire Rod Mill Production Line

Production Process of Wire Rod

Laying Head of Wire Rod Mill

Characteristics and Quality of Steel Wire Rod

Sendzimir Mill Features

What are the Main Advantages of the Step-Type Cooling Bed?

Walking Beam Cooling Bed

Morgan Wire Rod Mill

What is a Cold Roll?

Crank Type Flying Shear

What is the Difference Between a 2 Hi Rolling Mill and a 4 Hi Rolling Mill?

What is the Universal Mill?

Why does the Steel Bar Bend after being Cut by Flying Shears?

Aluminum Rolling Mill Process

Continuous Rolling, Semi-continuous and Slit Rolling Processes of Rolling Mills

What’s the difference between hot and cold rolling mills?

Oil and Gas Lubrication in Bearing of High-Speed Rolling Mill

High-Speed Wire Rod Finishing Mill’s Troubleshooting Method for Burning Bearing Bush of Roller Box

What are the Main Accessories of the Rolling Mills?

Features of Hot Rolling and Controlled Cooling

Headless Welding Rolling Process

Bar Rolling Mills Water Cooling Technology

What is Wire Rod Mill?

Raw Material of Monoblock Mill (Wire Rod Mill)

Products of High-Speed Wire Rod Mill

Causes of Surface Cracks in Wire Rod Rolling Mill

Aluminum Hot Rolling Mill

Billet Selection and Heating of Hot Rolled Wire Rod Mill

Finishing Mill Main Features

What is Slit Rolling?

Causes and Solutions of Steel Piling-up in Wire Rod Rolling Mills?

Bar Automatic Counting System

Rebar Rolling Mills Control Cooling Method after Rolling

Monoblock Wire Rod Mill High-Quality Control

Rolling Mill Pass Design Selection

What is the Rolling Steel Production Process?

How to Improve the Production Efficiency of Cold Rolling Mills?

Main Methods of Wire Rod Rolling

Main Causes and Solutions of Vibration of Laying Head

Hot Tinning Plating Production Process

Sendzimir Mill

No comments:

Post a Comment