One of the main operational faults encountered in continuous casting is "steel leakage". When the shell of the casting billet breaks down, the static molten steel in the shell overflows and blocks the machine, which requires expensive shutdown costs. In order to pull out the billet shell, the stop time caused by the steel leakage should be extended, because it may block the guide roller or foot roller. It needs to be cleaned and blocked by gas cutting and pulled out the blank shell.

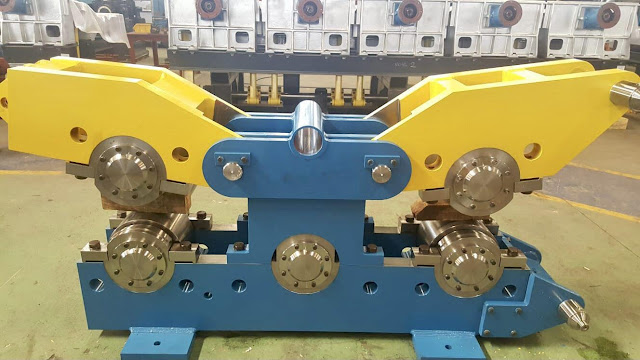

When the missing billet shell temperature decreases, it needs to be cut into small pieces and taken out of the machine by a straightener. The straightener is designed to straighten the curved cold billet shell gradually in a stable stage. The upper roller can provide enough lifting gravity to make the bending casting flow not too long. Therefore, the steel leakage has a significant impact on the effectiveness of the continuous caster - affecting productivity and production cost.

Influencing factors of steel leakage:

1. Temperature and pulling speed are not consistent.

The higher the superheat of molten steel, the thinner the thickness of the shell. Due to the static pressure exerted by the molten steel in the mould, the shell of the billet expands. When the strength of the shell is not enough, it is easy to leak steel. The inconsistent and uneven temperature has a great influence on the steel leakage. When the pulling speed increases, it is easy to leak steel, because the mould is not lubricated enough, and the fluidity of mould protection slag is poor from the meniscus to the shell/mould wall, and the increase of the pulling speed will lead to the decrease of total heat release.

The steel leakage is often caused by too high pulling speed. When the billet shell does not have enough time to solidify to the required thickness, or the metal is too hot, this means that the final solidification happens just under the straightening roller. Due to the stress applied during straightening, the shell is torn. When the carbon content of steel is certain, the steel leakage is easy to occur when the temperature is high and the pulling speed is fast. Any change in the vibration setting will cause steel leakage, because the way of reducing the vibration mark by increasing the vibration frequency will increase the moulding rate and increase the friction at the interface.

2. Poor lubrication between mould and billet shell

If the poor quality protection slag is used, the steel under the meniscus is easy to contain slag, which leads to the bond between the mould and the shell, and the blank drawing is interrupted, and the suspension steel leakage is caused. During continuous casting, due to poor lubrication or uneven lubrication, the shell of the billet is bonded to the mould, which affects the heat transfer, resulting in bonding and steel leakage.

3. The method of adding the protective slag is incorrect

3. The method of adding the protective slag is incorrect

Because of the working habits of the workers on-site, too much is added at one time, and the main arc is concentrated in the arc, which is the slope, which will cause uneven filling of liquid slag, which will affect the lubrication and uniform heat transfer between the mould and the shell. Under normal pouring conditions, it is unnecessary to remove the small slag strip. It is forbidden to use the slag bar to test whether the slag strip is formed in the mould, which will damage the uniform formation of the initial shell of the meniscus.

4. Ineffective flow in the mould

4. Ineffective flow in the mould

Reducing the flow into the mold will lead to a reduction of heat transfer, resulting in the formation of a thin shell, and eventually steel leakage. The temperature, pressure and flow rate of the inlet and outlet directly affect the cooling of the crystallizer. The pressure increases and the flow rate decreases due to the blockage of the cooling system of the crystallizer, which affects the heat transfer and easily causes steel leakage. Therefore, the great difference of water temperature (high temperature) at the inlet and outlet leads to the bond between the mould and the shell, and the steel leakage is easy to be broken.

5. Improper mould geometry

In order to increase the contact surface of molten steel mould and adjust the taper of the mould to adapt to the solidification shrinkage of steel, thus increasing the heat transfer of the mould and increasing the thickness of the shell. For the traditional mould with linear taper on a high-speed billet continuous caster, the heat transfer at the meniscus makes the casting flow solidify into a solid shell rapidly. With the shrinkage of the shell, the corner is separated from the mould and the heat transfer stops. Therefore, at the bottom of the mould, the shell continues to grow except for the remelting of the corner. When the shell leaves the mould, the temperature of the shell changes greatly, and the increase of the pulling speed may lead to steel leakage. If the taper is not satisfied, an air gap will be generated between the mould and the shell. When the resistance of air to heat transfer in the mould reaches the maximum, it will seriously hinder the formation of the required thickness of the shell, and eventually lead to steel leakage. The taper loss of mould caused by wear and deformation will result in a significant increase in the longitudinal crack of the corner, which is due to the reheating of the corner.

As far as the mould deformation is concerned, the reason is that the thickness of the copper plate is thin, which is not enough to support the thermal expansion of the copper plate. It may also be that when the ingot bar is inserted into the mould, the lower part of the mould will be damaged and the mould will be deformed. The taper of the mould increases the drag of the blank drawing, which leads to the increase of mould wear. The thickness of the air gap increases with the increase of taper and heat shrinkage, and then the wear of the large corner is added. Therefore, the heat transfer which causes the surface temperature to rise should be reduced. This phenomenon always accompanies the hydrostatic pressure of steel, which will induce tensile strain on the corner surface, which leads to cracks. This kind of crack will reduce the thickness of the shell by fixing, which may lead to steel leakage. The larger the radius of the mould fillet, the larger the air gap. The air gap hinders the heat transfer, which leads to the formation of thin billet shell, which is easy to leak steel. In slab/bloom caster, four separate copper plates are fixed to form holes around them. If there is air gap between the two copper plates, the initial metal will penetrate the air gap and start to solidify, and cause suspension in the later stage, leading to steel leakage. Therefore, improper adjustment of the crystallizer will affect the heat transfer mechanism and cause steel leakage.

6. The steel level in the mould is not suitable

6. The steel level in the mould is not suitable

During continuous casting, the steel level in the mould should be maintained at 70% - 80% of the mould height. If the steel level falls below the immersion nozzle, the solidified shell formed by the subsequent addition of molten steel is thinner and easy to leak. Steel level drop may occur during the plugging of the water inlet, tundish or tundish. When the molten steel is restricted from the tundish to the mould, if the pulling speed is not adjusted, the steel leakage may occur. Therefore, if the control of plug rod is not suitable, the rotation causes the steel overflow, and the sticking to the top of the mould will cause suspension and block drawing, and lead to steel leakage. The decrease of steel level will also cause slag inclusion. If there is sufficient time for the plug bar to close the immersion nozzle, the steel level can be reduced to below the allowable limit. If the pouring starts again, the molten steel will inhibit the mold protection slag, resulting in slag inclusion.

Therefore, when the ladle is completely cast, the steel level of tundish will drop. If the operation is not correct, the slag can enter the steel water in the mould through the immersion nozzle. The oxidation products of steel flow, improper deoxidation products, and high viscosity slag formed by the high Al2O3 caused by improper spraying of aluminium wire in billet mould may infiltrate into the shell to form slag inclusion, locally inhibit the formation of billet shell, reduce the lubrication between the shell and the mould, and easily bond, which will lead to the interruption of drawing billet and steel leakage. For the automatic control system of the diameter nozzle, the instability of the molten steel level in the mould will cause the fluctuation of the pulling speed, which will affect the stable filling of the slag into the mould and the shell, destroy the continuity of the slag film, and easily make the thickness of the shell uneven, and cause the surface depression or corner crack and steel leakage. The liquid level fluctuates greatly when replacing the immersion nozzle in production, and it also easily causes corner crack or slag leakage.

7. Eccentric pouring flow in the tundish

7. Eccentric pouring flow in the tundish

The eccentric pouring flow of tundish leads to uneven heat transfer, uneven thickness of solidified shell, decrease of strength at the weak part of billet shell, and it is difficult to bear static pressure of molten steel, so steel leakage is caused. The misalignment of immersion nozzle, the center of steel flow is slanted, the local erosion of billet shell is serious, the uniformity of cooling of the shell in the mould will be greatly affected, and the steel leakage will also be caused when it is serious. The tundish shell is easy to deform locally for a long time, which causes the water inlet to be out of alignment or the insertion depth is not uniform; Improper installation of upper water inlet and block during repair and tundish will also cause the misalignment of immersion nozzle. In production, the center of the nozzle can be judged by comparing the vibration mark depth of the surface of the billet shell.

8. The air mist cooling nozzle is blocked

8. The air mist cooling nozzle is blocked

The foot roller area is located under the mould, and the water is directly sprayed on the shell through the nozzle. The blank shell is under the pressure of the roller, making the shell smoother. At this time, the heat transfer is the largest, which is convenient to form a thicker shell. If the nozzle is blocked, the thickness of the shell will become thinner, which will easily cause steel leakage. In case of blockage, external force shall be applied by pulling roller. If the limit is exceeded, the surface of the shell will be broken and steel leakage will be caused.

9. Ingot bar irregularity

Once the molten steel solidifies above the ingot bar of the mould, forming a blank shell of sufficient thickness, the ingot bar will be pulled out slowly. If the ingot bar is not pulled out according to the rules, steel leakage will easily occur. Similarly, the poor assembly of the dummy bar will cause the molten steel to flow out of the mould, leading to steel leakage. If the ingot bar is separated from the shell before the head of the dummy bar is lifted, it will lead to steel leakage.

According to the appearance of the shell, the steel leakage is divided into the following categories:

10. Suspension or bonding causes steel leakage

According to the appearance of the shell, the steel leakage is divided into the following categories:

10. Suspension or bonding causes steel leakage

The water of steel is bonded to the mould, and therefore is called bonding or hanging. This may be caused by improper lubrication between the mould and the shell or improper adjustment of the mould. The improper lubrication may be caused by the poor quality of the protection slag, slag inclusion in the shell of the mould, overflow of the molten steel of the mould, corner joint of the mould, and poor/unequal operation of the billet caster.

11. The cracks cause the steel leakage

11. The cracks cause the steel leakage

Longitudinal crack at the corner of the shell and the longitudinal crack in the wide plane will cause steel leakage. If longitudinal crack causes steel leakage, the flow of the slag is uneven, the uneven heat transfer of the mould results in the uneven thickness of the shell, improper selection of the protection slag and uneven cooling of the mould causes the shell rupture during cooling. For the steel leakage caused by a diagonal longitudinal crack, the shell with insufficient solidification thickness along the narrow surface of the mould breaks due to the tensile stress when it contracts. The tensile stress is caused by the decrease of taper of the narrow surface and uneven heat transfer on the narrow surface of the mould.

12. Slag inclusion and steel leakage

12. Slag inclusion and steel leakage

The heat transfer is reduced due to the inclusion of protective slag or large particle inclusions in the shell, which leads to the formation of a thin shell and steel leakage. During billet continuous casting, secondary oxidation products, improper deoxidation products in high viscosity slag during low carbon steel smelting, improper injection of aluminium wire in the mould cause high Al2O3, which all promote slag inclusion in the shell, inhibit the growth of billet shell and cause steel leakage.

13. Thin shell steel leakage

13. Thin shell steel leakage

The observation of such steel leakage in billet caster is caused by uneven thickness of billet shell in the mould, which may be caused by eccentric casting flow in the mold or serious deformation of cooling pipe of mould.

14. Stop pouring causes steel leakage

14. Stop pouring causes steel leakage

The continuous casting process breaks and fails to break the stop pouring. If the joint point cannot bear the pull force imposed by the recasting, the whole furnace steel will leak.

The measures to control the steel leakage should take necessary measures to control the occurrence of the steel leakage, considering the influence of the steel leakage on the utilization and effectiveness of the continuous casting machine.

● Only temperature measurement shall be conducted after argon blowing on the pouring platform to ensure the uniformity of temperature.

● Only temperature measurement shall be conducted after argon blowing on the pouring platform to ensure the uniformity of temperature.

According to the chemical composition of steel, the pouring flow temperature must be kept over temperature of about 60 ℃ to place the ladle on the rotary table to ensure that the molten steel overheated 25-35 ℃ in the tundish.

● Control the speed of pulling according to the temperature monitored in the ladle.

● Control the speed of pulling according to the temperature monitored in the ladle.

The carbon content in steel is fixed one by one to ensure that the temperature increases with the decrease of the pulling speed and the pulling speed increase with the decrease of temperature. Therefore, the pulling speed should be adjusted correctly according to the temperature and carbon content of the steel. The speed of the continuous casting is increased gradually, and the steady continuous casting is maintained by a certain pulling speed. Any interruption in continuous casting should reduce the speed of pulling.

● Any protective slag has a valid period, so it should not be used after the expiration date.

● Any protective slag has a valid period, so it should not be used after the expiration date.

The protective slag can only be opened during casting and dried under a high wattage bulb. The protective slag of the open bag shall not be used in casting again. Select the appropriate protective slag according to the specified chemical composition of the steel. At the beginning of casting, initial protective slag with low viscosity and low melting point shall be used. For billet caster, it is necessary to ensure that linseed oil is distributed evenly in mould.

● For slab/bloom caster, measure the thickness of slag pool to determine whether the thickness of slag pool is more than 10 mm and the equipment stroke composed of steel, copper and aluminium wires attached to the steel plate, which helps to avoid uniform lubrication of slag inclusion and shell.

● For a high-speed billet caster, various taper crystallizers can be used instead of traditional linear taper crystallizers. To check the mould deformation (if any). The taper of the mould is selected and the taper is adjusted according to the steel rhyme grade and the solidification mode of the mould on the slab/bloom caster to adapt to the narrow surface.

● Before the continuous casting, check the water flow in the mould and find out the blockage (if any) by measuring the increase of water pressure.

● For slab/bloom caster, measure the thickness of slag pool to determine whether the thickness of slag pool is more than 10 mm and the equipment stroke composed of steel, copper and aluminium wires attached to the steel plate, which helps to avoid uniform lubrication of slag inclusion and shell.

● For a high-speed billet caster, various taper crystallizers can be used instead of traditional linear taper crystallizers. To check the mould deformation (if any). The taper of the mould is selected and the taper is adjusted according to the steel rhyme grade and the solidification mode of the mould on the slab/bloom caster to adapt to the narrow surface.

● Before the continuous casting, check the water flow in the mould and find out the blockage (if any) by measuring the increase of water pressure.

In general, check the difference of water temperature, pressure and flow at the inlet and outlet, and flow equipment. The water quality should also be checked. According to the grade of steel and its solidification mode, the cooling mode of mould, i.e. water flow rate (1 / min), is adjusted to adapt to various mould surfaces. In order to control the bonding, the thermocouple was used to detect the change of mould wall temperature and reduce the pulling speed to make the shell grow evenly. For a given caster, ensure that the inlet and outlet water temperature difference cannot exceed the specified value during continuous casting.

● Ensure that the maximum radius of the fillet along the copper plate is 0.2mm.

● Ensure that the maximum radius of the fillet along the copper plate is 0.2mm.

If corner joints exist at the copper plate joints, the corner joints shall be filled with gypsum or lime before continuous casting.

● Install the mould level automatic controller on the continuous casting machine to keep the steel level of the mould.

● Install the mould level automatic controller on the continuous casting machine to keep the steel level of the mould.

In order to distinguish the molten steel and slag in the mould and check the slag inclusion, the electromagnetic sensor is installed on the mould.

● Before casting, adjust the tundish nozzle and carry out alignment.

● Before casting, adjust the tundish nozzle and carry out alignment.

Before the tundish water inlet is blocked, before the ladle is placed on the rotary table, it is necessary to ensure that the wire of Ca Si core is injected into the steel, which meets the requirements of high aluminium steel, so as to form low melting point calcium aluminate. Use a cryostat to avoid the rod from turning.

● By using metal protective flux in tundish and shielding plate between ladle and tundish, it is necessary to ensure that deoxidation products are appropriate to prevent the formation of secondary oxidation products. Mn / Si > 3 shall be maintained for the billet caster.

● Seal the spindle rod head with asbestos rope and use the quench box to ensure the correct distribution of the quench box before casting.

● To check the blockage (if any), check the spray cooling nozzle and water flow.

● By using metal protective flux in tundish and shielding plate between ladle and tundish, it is necessary to ensure that deoxidation products are appropriate to prevent the formation of secondary oxidation products. Mn / Si > 3 shall be maintained for the billet caster.

● Seal the spindle rod head with asbestos rope and use the quench box to ensure the correct distribution of the quench box before casting.

● To check the blockage (if any), check the spray cooling nozzle and water flow.

Looking for the continuous caster or relevant spare parts, please mail at marketing2@hanrm.com.

More Articles You May Be Interested:

No comments:

Post a Comment