1. Overview

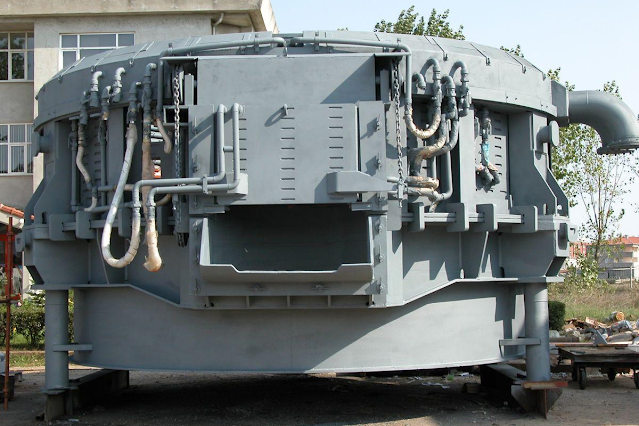

The 6300kVA electric arc furnace is designed and manufactured according to GBl0067.14 "Basic Technical Conditions for Electric Heating Equipment". It is used for alloy smelting, the furnace body is fixed, one tap nozzle and one slag outlet are included.

2. Mechanical Structure Description

The 6300kVA high-titanium slag electric arc furnace is a fixed furnace body. The top of the fume hood is charged, and the tapping nozzle is in the form of tapping. It consists of the following parts: furnace shell, water-cooled furnace cover, electrode lifting device, high current circuit, hydraulic system, Water cooling system, feeding device, transformer, high voltage cabinet, low voltage electrical control system, etc.

3. Furnace

The furnace body includes the furnace shell, the tapping nozzle, and so on.

The furnace shell is welded with a 16mm Q235 steel plate. To increase the rigidity, ribs are provided on the outside of the furnace shell. A tapping nozzle is opened on one side of the furnace shell, and the furnace shell is lined with refractory materials.

4. Water-cooled Furnace Cover

The water-cooled furnace cover is a device for collecting smoke and dust in the furnace. It can be placed on the furnace shell or on the furnace mouth operating platform. The water-cooled furnace cover is made of 20g seamless steel pipe. The entire furnace cover must be well insulated to the ground, generally not less than 0.2MΩ. There is a flue on the top of the hood, and the flue is partially cooled by water. The water-cooled furnace cover is equipped with three-electrode holes, feeding holes, and observation holes.

5. Electrode Lifting Device

The electrode lifting device is composed of an electrode arm, a column, an electrode clamping mechanism, an electrode lifting hydraulic cylinder, a bracket, a guide wheel, and so on.

The electrode arm is a conductive cross arm, which is a fully water-cooled box-shaped structure made of copper-steel composite plates. The side surface of the front section of the side-phase cross arm and the front section of the middle-phase cross arm are respectively equipped with electrode clamping mechanisms. The electrode clamping adopts the form of disc spring, that is, the electrode is clamped by the disc spring during normal operation, and the disc spring is compressed by the hydraulic cylinder when the electrode is released.

The conductive part is insulated from the ground once, that is, the cross arm and the column are insulated by insulating cloth plates. The electrode distribution circle can be adjusted ± 50mm。

The column is a box-shaped central member welded by steel plates. It is installed upright in a mechanism equipped with guide wheels, and the guide wheels are in close contact with the column. An electrode lifting hydraulic cylinder is installed in the hollow column. The upper part of the hydraulic cylinder is connected with the electrode column, and the lower end is connected with the bracket. The electrode lifting hydraulic cylinder pushes the column to raise the electrode arm and electrode. When it descends, it is completed by its own weight. The connection between the column and the cross arm is through the intermediate adjustment plate, so that the connecting surface of the cross arm and the column is both an insulating surface and a separate surface, so that not only the adjustment of the cross arm is convenient, but the insulation between the column and the cross arm is also more reliable.

The electrode clamping mechanism is composed of an electrode clamping disc spring, connecting rod, brake, hydraulic cylinder, etc. The hydraulic cylinder and the disc spring realize the clamping and loosening of the electrode through the connecting rod and the holding brake. When the electrode is loosened, a hydraulic cylinder drives and compresses the disc spring to realize the electrode loosening. The bracket is used to connect the electrode lifting mechanism and the furnace cover lifting and rotating mechanism, so that the load of the electrode lifting mechanism is supported on the rotating frame of the furnace cover lifting and rotating mechanism through the supporting plate and the pin shaft.

During the lifting and lowering of the electrode, the guide wheel acts as a guide through the column. At the same time, in the process of furnace debugging, adjust the front, rear, left and right positions of the column by adjusting the position of the guide wheel to adjust the diameter of the electrode distribution circle.

6. High Current Circuit

The high-current line consists of connecting copper bars at the second outlet of the electric furnace transformer, compensators, copper pipes through the wall, cable joints, large cross-section water-cooled cables, conductive cross arms, electrode clamps, graphite electrodes, and brackets.

Copper bolts or stainless steel bolts are used to connect the water-cooled cable to the copper pipe through the wall and the conductive cross arm. Through-wall copper pipes, water-cooled cables, and conductive cross-arms are cooled by water.

7. Hydraulic System

The pressure of the hydraulic system is 12MPa, and the working medium is water-glycol. The system includes hydraulic pressure source and various control valves, accumulator tank, accumulator, pressure relay, etc. The hydraulic source has two pumps, and the liquid storage tank is equipped with temperature and liquid level control instruments.

8. Cooling Water System

The cooling water system consists of pressure gauges, thermometers, shut-off valves, water distributors, return tanks and pipelines.

The cooling water source is connected to the main water inlet pipe of the workshop, the pressure is not less than 2×lO5Pa, and the water temperature is not more than 35°C. The device is equipped with water pressure and water temperature alarms, when the water pressure is lower than the set value or the water temperature is higher than the specified value, an alarm signal will be issued.

The cooling water device is located in front of the furnace on the side of the transformer room wall, and is cooled with the furnace body through pipelines (including hoses)

The parts are connected for cooling of the furnace body, furnace cover, conductive cross arm, water-cooled cable and copper pipe through the wall.

The water for the transformer oil-water cooler is supplied by the high-level cooling water tank, and the return water is connected to the workshop return water network.

9. Compressed Air System

The system consists of pneumatic triple parts, distributors and solenoid valves.

10. Feeding Device

The feeding device is composed of a hopper, an air cylinder, a vibrating feeder, and a feeding tube.

11. Electrical Equipment

The electrical equipment mainly includes a high-voltage power supply system, furnace transformer, low-voltage power supply system, low-voltage electrical control system, and electrode lifting automatic regulation system.

Looking for an electric arc furnace or any relevant spare parts, please mail at marketing2@hanrm.com, our tech engineer will make a suitable solution for you.

Hi to every single one, it’s truly a good for me to visit this web page, I love your content, they are very nice and it includes helpful Information. Check out our website SS fasteners manufacturers in India for more Siddhagiri Metals & Tubes related info! I am truly pleased to read this website posts which carries lots of helpful data, thanks for providing these kinds of statistics.

ReplyDeleteVery informative article, which you have shared here. After reading your article I got very much information and it is very useful for me. You can also visit High Tensile Fasteners manufacturers in india for more Vinesh Steel related information and knowledge, I am thankful to you for sharing this article here.

ReplyDeleteIt was such a good post. Visit astm a420 wpl6. Thanks for sharing.

ReplyDelete